EVO PRO TI - Josh Amberger

12th Jan 2024

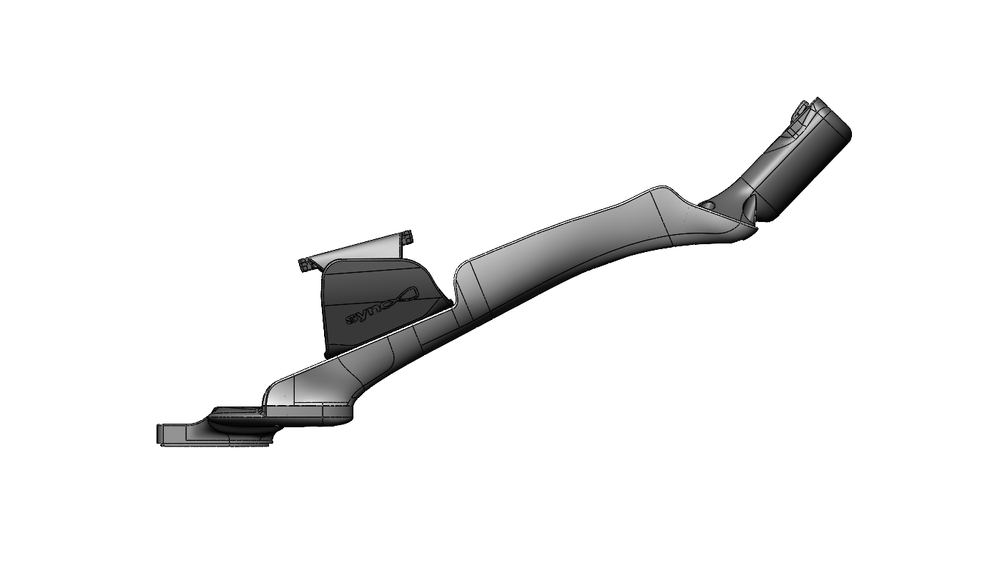

When ultimate performance is the end goal, to what extent do you go to push the boundaries? At the top of our product offering sits the EVO PRO TI extensions, a product that utilises 3D printing technology to push the boundaries of position optimisation and maximise aero performance.

Why 3D printed Ti?

Every manufacturing technique has its pros and cons, but for us in the application of 3D printing extensions, Ti offers three main advantages:

1) The ability to develop a unique profile, for any one individual, factoring in the geometry of their bike (eg the reach measurement) and also the geometry of the lower surface of an athletes forearm.

2) The ability to build in strength qualities, to key areas of the product, through manipulation of the internal structure, while retaining a thin outer shell.

3) 3D printing offers the ability to produce parts with a lower minimum order quantity (essentially a single set of Ti extensions). Small-scale production is ultimately a requirement of developing truly custom components.

A key benefit of 3D printing technology is the ability to produce almost any shape. Complex shapes are often easy to imagine, but are inherently hard to design. It goes without saying, the investment in time (during the whole manufacturing process) shifts toward the design process (as opposed to manual labour). The reliance on design means that the outcome is limited by the information (3D scan data) that underpins design.

The goal of a custom extension is to produce the sleekest possible design, integrating with the rider's forearm, while supporting an optimal TT position. Balancing the structural competing factors (shell profile, internal structural elements, the printing of threads and critical interfaces) is the challenge, in the quest for the most minimal design.

While balancing these competing factors is design intensive, the ability to heavily manipulate the internal structure is also highly beneficial. This allows us to maximise strength where it's needed and minimise the unnecessary material where it is not needed.

Weight is a consideration, not the main goal

For a Triathlete on a TT bike, weight (system mass) is less of an issue than for a road cyclist. While minimising weight is a consideration with the EVO PRO TI extensions, it’s not the primary goal. Our goal for mass is to match our standard EVO components. Given the EVO PRO TI extensions are more than double the cross-section of the parts they are replacing, this puts the “mass question” in perspective.

Each extension comes in at 199 grams. The mono grip is 84 grams. The arm cups are 87 grams for the pair.

Aerodynamic performance is the goal

What's more relevant than weight is aero performance - More than 90% of resistance to forward motion is in the form of aerodynamic drag, 70% of this comes down to airflow over the cyclist, 30% airflow over the bike and this product is designed to manipulate both of these.

Firstly in the optimisation of the position of the athlete, which stands as the largest influence on their overall aero performance. This is manipulation of that 70% factor in the overall "drag equation" and in the case of Josh Amberger's extensions it is easy to see how we have managed his positional requirements, in the design of these aerobars.

The secondary objective of the EVO PRO extensions is to lower the CdA of the rider by controlling the flow over the extensions and forearms, in a way which lowers pressure drag. In a typical aerobar setup, the extensions and forearms are two distinct bodies, and interact with the oncoming flow as such. What we have done with the EVO PRO extensions is essentially form one body from the extension and forearm. The air has a smooth path to flow around the fairing/extension and forearm. This eliminates the low-pressure region of the flow between the extension and forearm, reducing the overall pressure drag.

Designed and built for Josh Amberger

The 3D printed Ti extensions are only one outcome of the position optimisation process that we have been through with Josh. This journey has seen a range of macro changes to both his position and equipment choice. In addition, the design and build of his custom extensions has incorporated micro changes to truly optimise the outcome for performance.

The outcome of this is summed up in Josh’s experiences and we sure look forward to the opportunity for Josh to put this to the test in competition.

“My pedalling technique has improved, my aero position has improved. I’m riding faster and running faster off the bike”

Credits

Images by Stef Hanson(@stefhansonproductions)

Words by Ken Ballhause of Sync Ergonomics